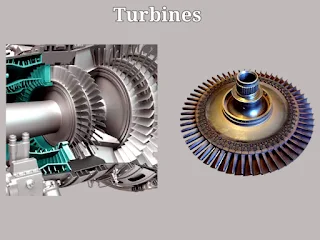

Turbines

The

turbine of gas turbine engine transforms a portion of the kinetic (velocity)

energy of the exhaust gases into mechanical energy to drive the gas generator

compressor and accessories. The sole purpose of the gas generator turbine is to

absorb approximately 60 to 70 percent of the total pressure energy from the

exhaust gases and convert into mechanical energy. The exact amount of energy

absorption at the turbine is determined by the load the turbine is driving

(i.e., size and type of compressor, number of accessories installed, and the load

applied by the other turbine stages). These turbine stages can be used to drive

a low-pressure compressor (fan), propeller, and shaft in aircraft/helicopters.

The turbine section of a gas turbine engine is located aft of the combustion

chamber. Specifically, turbine is directly behind the combustion chamber

outlet.

Turbine Assembly

The

turbine assembly consists of two basic elements which is necessary to extract

power from exhaust gases: these two components are the turbine inlet guide

vanes and turbine disk. The stator element is known by a variety of names by

different of manufacturer, of which turbine inlet nozzle vanes, turbine inlet

guide vanes, and nozzle diaphragm are three of the most commonly used by the

industry. The turbine inlet nozzle vanes (nozzle guide vanes) are located

directly aft of the combustion chambers and immediately forward of the turbine

wheel. Turbine inlet nozzle vanes is the components which comes in contact with

highest or hottest temperature in the engine. The turbine inlet temperature

must be controlled, or damage will occur to the turbine inlet vanes, leading to

complete failure of the engine.

After

the combustion chamber the heat energy converted into the mass airflow and

delivered it evenly to the turbine inlet nozzles, the nozzles must prepare the

mass air flow to drive the turbine rotor blade. The stationary vanes of the

turbine inlet nozzles are contoured and set at such an angle that they form a

number of small nozzles discharging gas at an extremely high speed. The nozzle

converts a varying portion of the heat and pressure energy to velocity energy

that can then be converted to mechanical energy through the turbine blades of

an gas turbine engine.

Turbine Disk with Blade installed

Types

of Turbine Blade

There

are three types of turbine blades use in gas turbine engine: the impulse

turbine blade, reaction turbine blade, and the reaction-impulse turbine blade.

Impulse Turbine

The

bucket is another name for the impulse turbine blade. This is because the

direction of the energy changes as the air stream contacts the middle of the

blade, spinning the disc and rotor shaft. To improve the effectiveness of the

air stream striking the turbine blades or buckets, the turbine nozzle guiding

vanes can typically be changed during engine refurbishment and assembly.

Reaction Turbine

Reaction

turbine blades causes the disk to rotate by the aerodynamic action of the hot airstream

directed to flow past the blade at a particular angle in order to produce the

most efficient power from the turbine engine.

Reaction-Impulse Turbine

The

action of the impulse and response blade designs are combined in the

reaction-impulse turbine blade. At the blade root, the blade has a more

bucket-like impulse blade shape, while on the second half of the blade, at the

blade's outer end, it has a more airfoil-like reaction blade shape.

The

gases are directed at a specified angle in the direction of the turbine wheel

rotation as the turbine inlet nozzle's secondary function. It is crucial to aim

the gas flow from the nozzle in the general direction of turbine rotation

because it must enter the turbine blade tunnel while it is still revolving.

Turbine Inlet Nozzle Assembly

The

inner and outer shrouds between which the nozzle vanes are fastened make up the

turbine inlet nozzle assembly. Varied types and sizes of engines use different

numbers and sizes of inlet vanes.

There

are numerous ways to assemble the turbine inlet nozzle's vanes between the

outer and inner shrouds or rings. Although the layout and design of the actual

components may differ slightly, all turbine inlet nozzles must have one unusual

feature: the nozzle vanes must be made to accommodate thermal expansion.

Otherwise, the fast temperature variations would cause the metal components to

twist or distort severely.

There

are numerous ways to achieve the thermal expansion of turbine nozzles. One

technique requires the supporting inner and outer vane shrouds to be assembled

loosely.

Each

vane fits into a shroud slot that has been shaped to meet the vane's airfoil

shape. These slots provide a loose fit since they are somewhat larger than the

vanes. Inner and outer support rings, which increase strength and rigidity, are

encased by the inner and outer shrouds to offer additional support. The removal

of the nozzle vanes as a whole is also made easier by these support rings.

Without the rings, as the shrouds were taken off, the vanes might fall out.

Fitting

the vanes into the inner and outer shrouds is another technique of thermal

expansion construction; however, in this manner, the vanes are welded or

riveted into place. It is necessary to give a way for thermal expansion, so

either the inner or outer shroud ring is divided into sections. The segments

are divided by saw cuts, which allow for enough expansion to prevent stress and

warping of the vanes.

Turbine Shaft & Turbine Wheel

The turbine section's rotor component essentially consists of a shaft and a wheel. The turbine wheel, which has blades attached to a revolving disc, is a dynamically balanced component. The disc is then fastened to the engine's main power-transmitting shaft. The turbine assembly rotates at a very high speed as a result of the exhaust gases acting on the turbine wheel's blades as they exit the turbine inlet nozzle vanes. The turbine wheel experiences heavy centrifugal loads as a result of the high rotational speed, and the material's strength is also decreased by the high temperatures. In order to maintain safe turbine operation, the engine speed and temperature must be managed.

Without

blades, the turbine disc is referred regarded as such. The disc transforms into

the turbine wheel after the turbine blades are mounted. The disc serves as a

part that anchors the turbine blades. The blades may transfer the energy they

capture from the exhaust fumes to the rotor shaft because the disc is fastened

or welded to the shaft.

The

disc rim is in contact with the hot gases moving through the blades and picks

up a lot of heat from them. In addition, the rim conducts heat away from the

turbine blades. Therefore, disc rim temperatures are typically high and

significantly higher than the temperatures of the further away

a

part of the disk's inside. These temperature variations lead to the addition of

thermal stresses to the rotational stresses. Additionally, due to exposure to

high temperatures, turbine blades are typically more prone to operating damage

than compressor blades. The aforementioned pressures can be at least partially

relieved using a variety of techniques. Bleeding cooled air back onto the

disk's face is one such technique.

As

a byproduct of installing the blades, the disc can also be relieved of its heat

strains in this way. The rim of the disc has a number of broached grooves or

notches that follow the design of the blade root. In addition to providing

space for the disk's thermal expansion, these grooves enable the connection of

the turbine blades to the disc. The turbine blade can move when the disc is

cold because there is enough space between the blade root and the notch. As the

engine runs, the disc expands, reducing the clearance. Due to this, the blade

root adheres closely to the disc rim.

Most

often, alloy steel is used to manufacture the turbine shaft. The large torque

loads that are applied to it must be able to be absorbed by it.

There

are various ways to attach the shaft to the turbine disc. One technique

involves welding the disc to the shaft, which features a butt or protrusion to

serve as the joint. Another approach uses bolting. For this technique to work,

the disc face must have a machined surface on the shaft's hub. The bolts are

then fixed in tapped holes in the disc after being inserted via holes in the

shaft hub. Bolting is the more prevalent of the two connection strategies.

The

compressor rotor hub must have a way to attach the turbine shaft. Typically, a

spline cut on the shaft's forward end is used to do this. The coupling

mechanism between the compressor and turbine shafts accepts the spline. The

turbine shaft's splined end may fit into a splined recess in the compressor

rotor hub if no coupling is utilised. As opposed to axial compressor engines,

which can employ either of the two described techniques, centrifugal compressor

engines generally exclusively use this splined coupling configuration.

Turbine blade attaching method

Turbine

blades can be attached in a variety of methods, some of which are comparable to

compressor blade attachment. The fir-tree design is the one that works best.

There

are other ways to keep the blades in their specific grooves, but the most

popular ones are peening, welding, lock tabs, and riveting.

Numerous

applications of the peening method of blade retention are common. One of the

most popular peening applications is for a small notch to be ground into the

blade's edge near the fir-tree root before the blade is installed. The metal

from the disc "flows" into the notch once the blade is put into it

through a small punch mark that was produced in the disc next to the notch.

This task requires an instrument that resembles a centre punch.

Another

technique for blade retention is to build the blade's root so that it has all

the components required for retention. In this technique, the tang is located

on one end of the blade root and acts as a stop to prevent the blade from being

inserted or removed in any other direction. To keep the blade in the disk, the

tang is bent.

Depending

on the makeup of the metals, turbine blades may be either forged or cast. The

majority of blades are precisely cast and shape-finished ground. Since several

turbine blades are made as a single crystal, the blades' strength and heat

conductivity are improved. The turbine blades and inlet nozzles are kept colder

by heat barrier coating, such as ceramic coating, and air flow cooling. As a

result, the engine's efficiency can be increased by raising the exhaust

temperature.

Although

a second form of turbine known as the shrouded turbine is occasionally

employed, the majority of turbines have open blade perimeters. In reality, the

shrouded turbine blades create a band around the turbine wheel's outer edge. As

a result, stage weights can be reduced and efficiency and vibration

characteristics are improved. However, it restricts turbine speed and

necessitates larger blades.

It

is occasionally required to use more than one stage of turbines while building

turbine rotors. It is frequently necessary to add extra turbine stages since a

single turbine wheel is frequently incapable of absorbing sufficient power from

the exhaust gases to drive the components that depend on the turbine for

rotative power.

A

row of still vanes or nozzles is followed by a row of revolving blades in a

turbine stage. Up to five turbine stages have been effectively used in various

turboprop engine variants. It should be kept in mind that there is always a

turbine nozzle before each wheel, regardless of the number of wheels required

to drive engine components.

The

employment of more than one turbine wheel is occasionally justified in

situations of high rotational loads, as was highlighted in the discussion of

turbine stages that came before it. Additionally, it should be noted that

numerous compressor rotors are frequently advantageous when used in conjunction

with the same loads that call for multistage turbines.

In

a one-stage rotor turbine, a single turbine rotor generates all of the power,

and this wheel drives all engine-driven components. On engines when the demand

for low weight and compactness is paramount, this design is used. The pure

turbojet engine in this form is the most basic.

Each

spool in an engine with several spools has a unique set of turbine stages. The

compressor connected to each turbine stage rotates. The majority of turbofan

engines feature two spools: a low pressure turbine and a high pressure turbine

to drive the fan shaft.

The

turbine housing or casing is the final topic to be covered in relation to

familiarising yourself with turbines. The stator components of the turbine

section are either directly or indirectly supported by the turbine casing while

also enclosing the turbine wheel and nozzle vane assembly. It is always

equipped with front and rear flanges for attaching the assembly to the exhaust

cone assembly and the combustion chamber housing, respectively.

Turbine Design Considerations

Both

high rotor speeds and high temperatures are used to turbines. Due to the high

temperatures and high centrifugal forces produced by high rotor speeds,

turbines must operate within a range of temperatures that, if exceeded, will

weaken the materials used to construct them. Turbine blades experience a

distortion known as creep over time. Creep refers to the blade's stretching or

lengthening. The strength of the blade, which is influenced by the temperature

in the turbine, and the load placed on the turbine both affect how quickly this

situation creeps.

The

turbine wheel, which has blades made of metal alloy linked to a revolving disc,

is a dynamically balanced component. To enable it to be firmly attached to the

disc and still provide room for growth, the base of the blade is often of the so-called

"fir tree" form. The tips of the rotating blades of some turbines are

open, but they are covered in others. Shrouded blades surround the turbine's

edge in a band, which lessens blade vibrations. Because the shrouds allow for

thinner, more effective blade sections than would otherwise be allowed due to

vibration concerns, the weight of the shrouded tips is offset. Additionally,

shrouds reduce gas loss around the turbine blade tips.

Improvement in Turbine Inlet Temperature

Increasing

the temperature of the turbine inlet is the most alluring way to improve thrust

and turbine power output. The requirement for better turbine blade materials

and effective cooling techniques is directly related to increases in turbine

inlet temperature.

Materials Considerations

The

features of metals and alloys' high-temperature strength have been the subject

of extensive research and are still being improved. As a result of this

endeavour, a number of cobalt- and nickel-based alloys have been developed that

significantly outperform iron-based alloys in terms of high temperature

strength. Newer, exotic materials offer even more potential. Blades formed of

materials that have been directionally solidified, exposed to high

solidification rates, or even made of a single crystal can now be produced

thanks to advancements in metallurgical processes.

Improved Temperatures Due to Improved Metallurgical Techniques

Ceramic

materials are being looked into by several manufacturers for usage in turbines.

While ceramic blades have a substantial advantage over metal ones in terms of

their capacity to endure high temperatures, issues related to stresses brought

on by centrifugal loads brought on by fast rotation rates present additional

challenges.

Turbine Blade Cooling

There

are numerous ways to cool turbine blades, but they all essentially involve

passing a cooling fluid through the blade to keep the metal's temperature

within acceptable operating ranges. In aviation gas turbine engines, this

cooling fluid is air drained from the compressor and directed onto the turbine

wheel's blades after travelling through internal engine channels. The standards

for achieving good cooling efficiency directly derive from the concepts of

fluid heat transfer in a closed duct. It is important to fulfil two fundamental

requirements in order to achieve high heat transfer rates in such a system,

namely,

(1)

flow the cooling fluid with a high Reynolds number, and

(2)

provide a large surface area for the energy flow path.

Given

these considerations, it is clear why a finned blade is far superior to an open

hollow blade. Because a boundary layer forms across the inner surface of the

open hollow blade, acting as a superb heat transfer insulator, very little

cooling occurs. When fins or tubes are inserted into the blade, cooling air is

forced to pass across a larger surface area while being very turbulent,

creating a turbulent boundary layer that easily transfers energy.

The

open hollow blade's limited structural capacity is another drawback. The open

hollow blade vibrates freely and with great magnitude at its resonance

frequency in the absence of fins or supporting parts, resulting in a

"breathing action" and fatigue failure.

There

are four general methods employed for blade cooling. These are:

- Convection

- Impingement

- Film

- Transpiration

- Turbine Cooling Methods

The

simplest way of cooling turbine blades was convection cooling, which was also

the first to be utilized. In the convection cooling process, internal

passageways in the turbine blade allow coolant air to flow outward from the

base to the tip. The size of the internal passageways in the blade and the

limitation on the amount of cooling air accessible limit the efficacy of

convection cooling.

As

a variation on convection cooling, impingement cooling involves turning the air

normal to the radial direction and passing it through a series of holes such

that it impinges on the inside of the blade at the desired cooling location.

Impingement cooling works incredibly well in small spaces and may be applied to

stator blades with ease. The leading edge of the blade, where the highest

temperatures are anticipated, is where this technique is typically used.

Compressor

bleed air is injected along the surface of the blades and vanes to cool the

film. This creates a layer of colder air that acts as insulation between the

metal of the blades and the hot gases coming from the combustor. Convection

cooling and impingement cooling are less efficient than film cooling.

The

turbine blades can function at higher temperatures thanks to a practical and

innovative technique called transpiration cooling. This technique uses a

sintered wire mesh to build the airfoil, which results in a blade with

thousands of cooling holes through which cooling air flows to shield the blade

from high-temperature gases. The airfoil needs an internal strut to carry the

structural and centrifugal loads because the material cannot support itself.

Cooling Effectiveness Comparison

Like

any other device that improves engine performance, cooling turbine blades has

both benefits and drawbacks. A superficial analysis of the turbine blade

cooling issue makes it appear as though the problem may be solved by simply

blowing compressor bleed air through hollow turbine blades. However, a more

thorough investigation of the matter will reveal how intricate the whole

turbine blade cooling issue is. Because the cooling air within the blades is

accelerated by centrifugal forces as it absorbs huge amounts of energy and

there is a tendency for gas choking, the fundamental problem of heat

transmission in a duct is rendered more challenging and intricate. Because the

coolant air bled from the compressor does not contribute to power extraction in

the turbine, an engine with cooled blades will perform significantly worse than

one with uncooled blades at a given turbine inlet temperature. Due to the

intricacy of the manufacturing process, pricing is arguably the biggest

drawback of turbine blade cooling.

As

has already been said, basic, open, hollow blades do not provide appropriate

cooling; however, blades with fins, inserts, and bundles of tubes are more

complicated to build but do so. These intricate cooled blades need to be

produced correctly. They must be able to endure the tremendous strains placed

on them by the centrifugal loads in addition to providing proper cooling. Manufacturing

the turbine rotor needed for cooled blades is equally challenging. The

air-sealing issue at the area where the coolant is delivered into the rotor hub

further complicates a rotor that supplies cooling air.

Also Read

Resolver (Electrical) | Rotary Electrical Transformer | What is the purpose of a resolver?

Full Authority Digital Engine Control (FADEC) System Description & Operation

0 Comments